Taking the Guardianship For Healthy Growth of All Skin Care Brands.

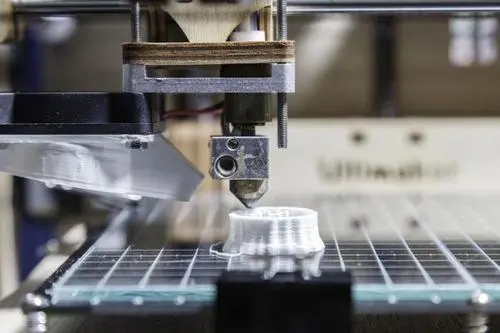

3D printing is an emerging technology in the field of manufacturing, which is called "manufacturing technology with industrial revolution significance". In recent years, with the progress of industrial technology, 3D printing technology has been developing rapidly and has been widely concerned by the media.

3D Printing

3D printing, also known as rapid prototyping, is a technique of constructing objects by printing layer by layer based on digital model files, also known as additive manufacturing. The basic principle of 3D printing is discrete - stack principle.

1.Principles of 3D Printing

Used in the daily life of ordinary printer can print computer design of planar objects, the so-called 3 d printers and working principle of the common printer basic same, just some different print material, ordinary printer to print material is ink and paper, and in the 3 d printer is equipped with metal, pottery and porcelain, plastic, sand and other different "printed materials", is real raw material, after connect with computer, printer with computer control can be "printed materials", one layer upon layer overlay, the blueprint of computer has finally become real.

In layman's terms, a 3D printer is a device that "prints" real 3D objects, such as a robot, a toy car, various models and even food. It is colloquially referred to as a "printer" because the layering process is very similar to ink-jet printing. The technology is called 3D printing.

There are many different technologies for 3D printing. They differ in the way they are made of available materials and built in different layers to create the parts. Common 3D printing materials include nylon glass fiber, durable nylon material, gypsum material, aluminum material, titanium alloy, stainless steel, silver plating, gold plating, rubber materials.

2.Advantages and disadvantages of 3D printing

High speed of finished products

Fast, efficient and low-cost 3D printing and injection molding have replaced time-consuming and expensive manufacturing techniques. Now, new developers can get an injection molding quote and know almost immediately how much it costs to bring a new product to market. Injection molding is a cost-competitive technique for making large numbers of the same plastic parts, and once the mold is created and the machine set up, other parts can be made very quickly and cheaply.

Accurate and varied configuration

3D printing makes it easy to create complex shapes, many of which cannot be generated by any other method of manufacturing. Even if the shape is complex, 3D printing technology can be used to complete product design and manufacturing. In the aircraft, automobile and other precision parts manufacturing has outstanding advantages.

No machining required

3D printing technology does not require machining or any mold to generate any shape of parts directly from computer graphic data. By doing so, the product development cycle can be greatly shortened, productivity can be raised, and production cost can be reduced. Compared with traditional technologies, 3D printing reduces costs and reduces material waste by eliminating production lines.

Product customization

3D printing not only offers greater design freedom, but also allows for complete customization of the design. Because current 3D printing technology can only produce a small number of parts at a time, it is ideal for small batch customization. The concept of customization has been adopted in medicine, dentistry, orthopedics and other fields for the production of customized prosthetics, implants and dental orthotics. From tailor-made advanced sports equipment and running shoes that are perfect for athletes to customized sunglasses and earrings, 3D printing can be used to produce customized parts in one time in a cost-effective manner.

Of course, 3D printing has its drawbacks as well as advantages. The following points are the disadvantages reflected in the application of 3D printing technology. With the progress of technology and the achievement of corresponding research results, these conditions are expected to improve in the future.

The printing effect is limited by the material

While high-end industries can print plastics, some metals or ceramics, the materials that can't currently be printed are expensive and scarce. From the perspective of the whole industry, the stability and ease of use of material quality still need to be improved, and the bottleneck of new material research and development is difficult to make a breakthrough in a short time. In addition, some 3D printing devices are not mature enough to support the various materials that people are exposed to in daily life.

Whether the finished product is durable

At present, polymer materials are commonly used in 3D printing, and each material has its own melting point, fluid and other properties. Therefore, it is difficult for 3D printing to cooperate with various materials, which leads to the defects such as great brittleness of printed products.

Intellectual property concerns

Nowadays, with the gradual strengthening of legal awareness, people pay more and more attention to the protection of intellectual property rights in music, film and TV industries, and 3D printing technology will also be involved in this issue. How to ensure that 3D printed products have legitimate copyright and are not misappropriated or used fraudulently has become a problem that must be solved in the process of industry development. How relevant departments formulate laws and regulations related to 3D printing to protect 3D printing intellectual property rights is also the key to the rational use of 3D printing.

It is difficult to overcome environmental factors

In the 3 d printing room, usually caused by a lack of air purification, cracks exist on a machine and metal powder mix some impurities such as material, print the oxygen content of indoor different happens, thus it will adverse impact on the mechanical properties of the parts to print, and it may even lead to parts of the chemical composition change, so to find a way to test print indoor oxygen content is one of the important measures.

3.Technology application

Now 3d printers with years of development, the FDM (fused deposition molding), FFF (fuse manufacturing forming), LOM (hierarchical entity manufacturing), SLS (selective laser sintering), SLA (three-dimensional light curing molding in), DLP (digital light processing), and other new technology constantly, one of the most representative is fused deposition molding technology (FDM), three-dimensional light curing technology (SLA), continuous liquid interface extraction technique (CLIP) and selective laser sintering (SLS) technology.

Molten deposition forming technology

FDM 3D printer technology is probably the most approachable additive manufacturing technology. It works by extrudingthermoplastic polymers through a heated nozzle and stacking them one layer at a time on a 3D printing plate to create a three-dimensional model. FDM 3D printers are the most affordable, especially for individuals or small and medium enterprises that don't have a big budget. Of course, if you love 3D printers, you can also find DIY 3D printer tutorials online, which is very convenient.

Stereoscopic photocuring technology

Stereoscopic photocuring technology is one of the additive manufacturing technologies proposed in the 1980s. It works by focusing a near-ultraviolet laser beam on a thin layer of liquid light polymer resin and rapidly rendering the designed plane. Then, the 3D printing model is finally formed by raising the liquid level and printing the next layer. The final step is to clean the resin material on the surface of the model and remove the final supporting structure.

Continuous liquid interface extraction technology

CLIP 3D printing technology works by projecting a continuous UV image produced by a digital light projector under the liquid resin through an oxygen-permeable UV transparent liquid level. It forms a dead zone above the liquid level. The cured part is extracted from the resin, and the cured part is directly pulled out from the dead zone.

Selective laser sintering technology

Selective laser sintering process is to use spread powder stick to tile a layer of powder materials in has formed on the surface of the parts, and heated to just below a certain temperature, the powder sintering point laser beam control system control according to the layer of cross section contour scanning in the powder, the powder of the temperature rise to melting point, sintering, and established under the partial implementation of the bond. After the sintering of the section of one layer is completed, the worktable decreases the thickness of one layer, and the paving roller lays a layer of uniform and dense powder on it, and then the sintering of the section of the new layer is carried out until the whole model is completed.

Compared to the first three technologies, the SLS does not require a supporting structure because its powder material can act as a self-supporting material. This allows the construction of complex and complex geometric shapes with almost complete design degrees of freedom. However, the cost of SLS 3D printer is also relatively high, which is why it is mainly used for industrial production applications.

4.Technological process

A. THREE-DIMENSIONAL design

The design process of 3D printing is as follows: firstly, the 3d model is modeled by the computer modeling software, and then the completed 3D model is "partitioned" into sections layer by layer, that is, slices, so as to guide the printer to print layer by layer.

B. Slicing

The printer reads the cross-section in the file, prints it out layer by layer in a liquid, powder or flake, and then stitches the sections together in various ways to create a single entity. The technology is characterized by the ability to make objects of almost any shape.

C. Complete printing

The resolution of the 3 d printer is adequate for most applications (in a curved surface can be rough, like image on the sawtooth), to get higher resolution items can be through the following methods: first, with the current 3 d printers with larger objects, then slightly after surface grinding smooth surface can be "high resolution" items.